Based on the packing list first the panels are shortlisted, which will become the major part of the designed panels. In the drawing based on the design and loading criteria’s. After all the shortlisted panels are consumed then the balance part Is designed with the remaining panels of the inventory which will get used after modification. Finally, the remaining blanks are filled with new components. likewise, the drawing is completed and ls forwarded to the design head for checking and review. once the comments from the design head is implemented then the drawing Is sent back for approval. From this approved modulation drawing, an IPO list ls created, which Is sub- categorized in 3 units namely:-

A. Used Directly

B. Modified and Re-used (Cut and welded)

C. New procurement

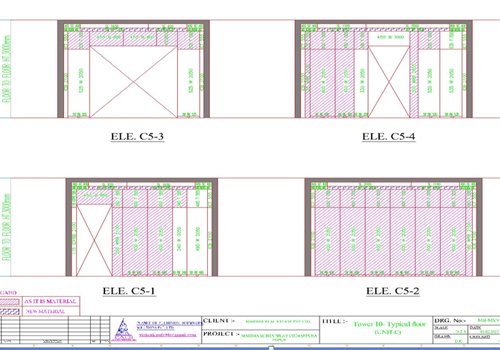

After the list is finalized then the re-usability percentage is calculated, and the same drawing is passed on If the re-usability Percentage is more than 80% of the total inventory area. Modulation drawing is prepared as per Aluminum formwork International standard scheme drawing. All the vertical formwork is shown in individual elevations, which makes the drawings easy to read, and even a labour foreman can understand the drawing and carry on erection on his own. After releasing Master BOQ including As it is / Modification / Not Found or Extra modify at site by Ideal Material.We will start the material shorting and modification as per master BOQ for upcoming sets. During the making Shell plan and Modulation drawings the Client ‘s Architect and Formwork team support us if any doubts and Problems regarding formwork. we will finalize the all working of design part within 15 days.

Our Activities for Formwork Re-Design and Modification Work

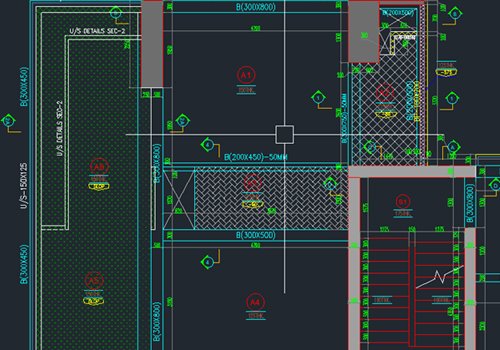

1. Making Shell Plan

Read All Architecture And Structure Details And Make Shell Plan. ( single short detail reinforcement plan) And Sections

. Shell Plan Revisions And Comments Of Shell Plan Will Continue To Be Approved.

2. Making Modulation Drawing.

3. BOQ. LISTS

Making the Master BOQ, list of whole Tower material as per Room wise.

• Providing Direct / To be Modify / Not Found or new Procurement material list. As per priority wise. For material shorting and Modify.

• Provide balance material list of old material.

4. MS ACCESSORIES.

• Providing Ms Accessories Drawing

• Providing Ms Accessories Adjustment with Stock for New Procurement.

REDESIGN REQUIREMENT

For Re-designing requirements are as follows.

1.) Packing List of old Material

2.)GFC DRAWINGS

1. final Typical floor Architecture plan

2. Typical floor Framing plan.

3. Typical floor beam detail.

4. Structure profile sections.

5. Staircase Secon detail.

6. Door/window Schedule.

7. Architecture Building all sides elevation.

8. Drip Mould detail.

9. Elevaon groove detail.

10. MEP plan.

11. MEP Elevaon detail.

12. Change floor drawing as same requirements if change in building.

Combining the available drawings, the shell plan is prepared which is approved by the client and based on approved shell drawing the designing of formwork is done. When The formwork designing is started the formwork drawing is called modulation.